A

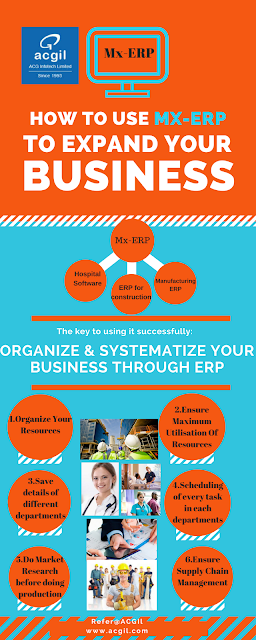

single tool in the manufacturing industry which focus on the organization to increase profits and margins, and strive to remain competitive at the same time. ERP Software is vital for manufacturing industries as it integrates and streamlines the department in the organization.

This software provides efficiency and delivers high-quality services to customers.

The manufacturing industry is dynamic and competitive which creates a

positive environment for business to integrate and flourish with enhanced efficiency, and minimal cost. This helps in increasing sales and profit and tries to make accurate decisions. ERP

Software allows business functions to operate smoothly.

Online ERP is helping various industries and clients to see benefits from manufacturing software.

-

Integrates with supply chain management - Enterprise Resource Planning manages the workflow of the material. This software helps in supply chain management as it requires a strong solution and understanding of multi-level tasking. Every country has a different strategy of the business and for supply management, they have to deal with different languages as well as currencies. To make this process easier the system integrates with the supply management and automates every transaction.

-

Improves production – Software provides the management of procuring, pricing of raw materials, also manages the schedule of employees, machine operations and maintenance to increase production. This system also helps in ensuring that the materials have been used properly and making end result profitable. Manufacturing ERP Solution allows just-in sequencing process, materials are ordered and scheduled as they arrive.

-

Improves customer experience – Software provides access to customer portal so that they can inquire about the availability, price, and delivery of the products. This system helps customers to place the order easily and provides quick delivery. This process helps in gaining customer's trust and they tend to incline towards the organization.

-

Automates a business with adaptability – ERP streamlines business and drives automation for the manufacturing industry. All the available data is centralized at a single location with visibility in all operations -development, designing, inventory, procurement, finance, sales, delivery, etc. It monitors production status in real-time, accelerates production and minimizes errors.

-

Better decision making – ERP Software provides complete visibility into every department and helps a company to take business decisions on the spot and faster. This solution enhances the decision-making ability of the company and also optimizes everyday operations.

-

Minimizes expenses – With the help of this system manual and time-consuming operations are replaced by an automated process and real-time business information. It increases worker productivity and minimizes labor costs. Transparency in the departmental operations helps to save money.